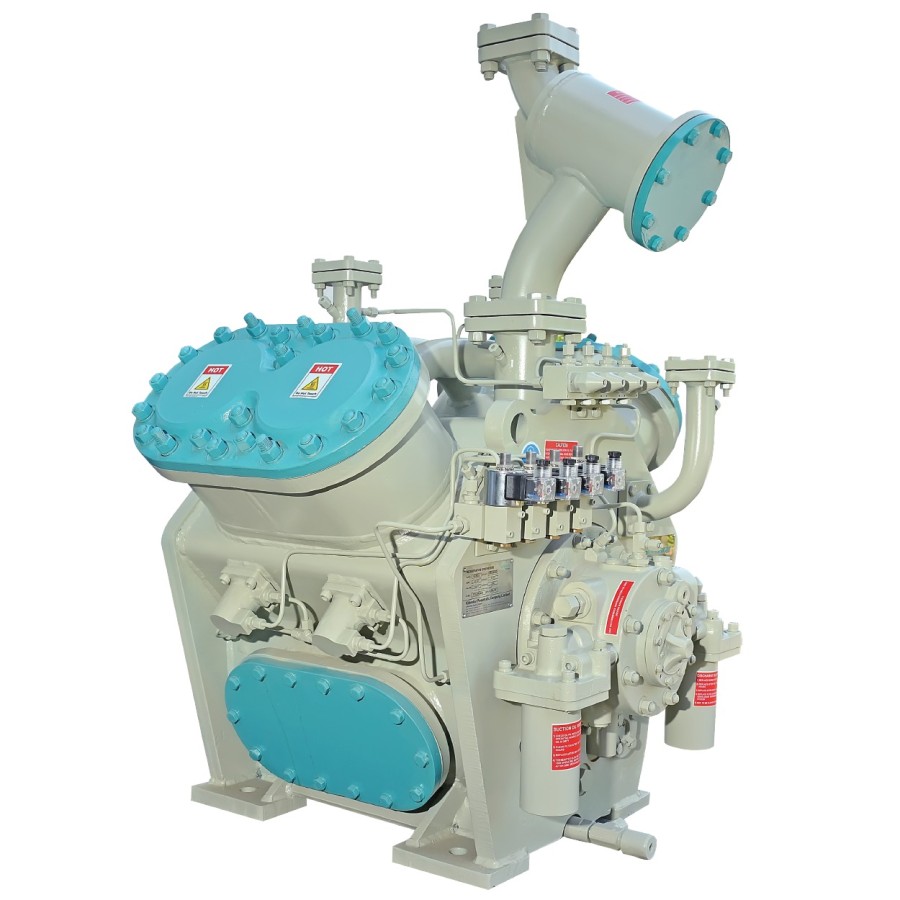

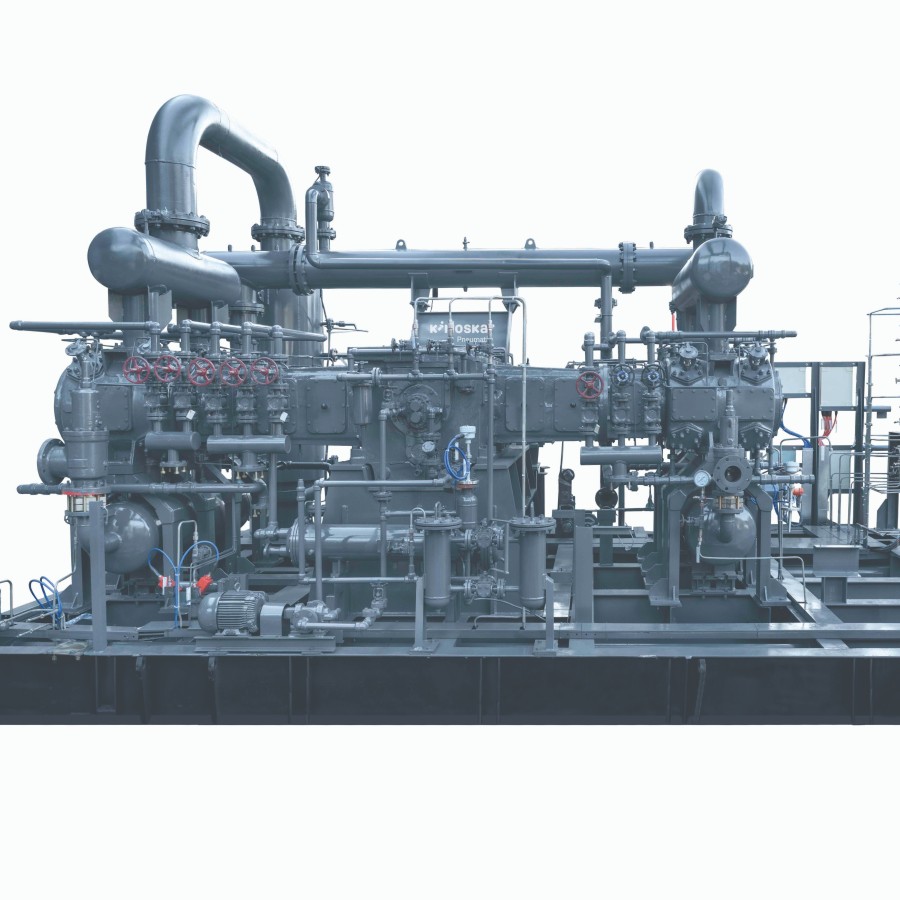

Kirloskar Ultra Efficient Vapour Absorption Chillers

By KIRLOSKAR PNEUMATIC CO LTD

Kirloskar’s Ultra Efficient Vapour Absorption Chillers are engineered to deliver cooling and heating solutions by utilizing untapped recoverable energy or live energy such as steam, hot water, and exhaust gas. This allows customers to dramatically reduce power consumption for cooling and heating, while also significantly reducing carbon footprints, Kirloskar’s Vapour Absorption Chillers operate on an advanced Para- flow design. This design ensures that there is no condition of low temperature and high concentration which makes the chiller crystallization free, ensuring the consistent, uninterrupted performance of the vapour absorption chiller. Kirloskar Vapour Absorption Chillers are widely used in all types of industrial facilities that generate waste heat, such as petrochemical, paper, food processing, and steel manufacturing, and in large commercial facilities. These advanced chillers are designed to optimize energy use and significantly reduce operational costs, setting new industry standards for efficiency and reliability and meeting customers’ requirements around the world.

Steam Driven Vapour Absorption Chillers

Single Effect Steam Driven Vapour Absorption Chiller

Capacity: 50 – 2000 TR

Heat Source: Steam

Steam Pressure: 0.5 – 3.0 kg/cm2(g)

COP: 0.75

Double Effect Steam Driven Vapour Absorption Chiller

Capacity: 50 – 2000 TR

Heat Source: Steam

Steam Pressure: 3.5 – 8.0 kg/cm2(g)

COP: 1.5

Hot Water Driven Vapour Absorption Chillers

Double Lift Hot Water Driven Vapour Absorption Chiller

Capacity: 50 – 1000 TR

Heat Source: Hot Water

Hot Water Temperature: 700c

COP: 0.41 to 0.71

Single Effect Hot Water Driven Vapour Absorption Chiller

Capacity: 50 – 1500 TR

Heat Source: Hot Water

Hot Water Temperature: 80 – 1200c

COP: 0.75

Double Effect Hot Water Driven Vapour Absorption Chiller

Capacity: 50 – 1500 TR

Heat Source: Hot Water

Hot Water Temperature: 160 – 1800c

COP: 1.5

Customized Offerings

Composite Chiller

Capacity: 25 – 200 TR

Brine Temperature: -35 to -5 °C

Refrigerant: R404, R134a, Ammonia

Heat Source: Steam / Hot Water / Exhaust Gas / Fuel

Zero Degree Vapour Absorption Chillers

Capacity: 50 – 1000 TR

Heat Source: Steam / Hot Water / Exhaust Gas / Fuel

Chiller + Hot Water Generator

Cooling Capacity: 50 – 2000 TR

Heating Capacity: 130 – 5275 kW

Heat Source: Steam / Hot Water / Exhaust / Fuel

Ultra Low Pressure Vapour Absorption Chiller

Capacity: 50 – 1000 TR

Heat Source: CP Vapour / Ultra Low Pressure Steam

Steam Pressure:

Steam Driven Vapour Absorption Chillers

Single Effect Steam Driven Vapour Absorption Chiller

Capacity: 50 – 2000 TR

Heat Source: Steam

Steam Pressure: 0.5 – 3.0 kg/cm2(g)

COP: 0.75

Double Effect Steam Driven Vapour Absorption Chiller

Capacity: 50 – 2000 TR

Heat Source: Steam

Steam Pressure: 3.5 – 8.0 kg/cm2(g)

COP: 1.5

Hot Water Driven Vapour Absorption Chillers

Double Lift Hot Water Driven Vapour Absorption Chiller

Capacity: 50 – 1000 TR

Heat Source: Hot Water

Hot Water Temperature: 700c

COP: 0.41 to 0.71

Single Effect Hot Water Driven Vapour Absorption Chiller

Capacity: 50 – 1500 TR

Heat Source: Hot Water

Hot Water Temperature: 80 – 1200c

COP: 0.75

Double Effect Hot Water Driven Vapour Absorption Chiller

Capacity: 50 – 1500 TR

Heat Source: Hot Water

Hot Water Temperature: 160 – 1800c

COP: 1.5

Customized Offerings

Composite Chiller

Capacity: 25 – 200 TR

Brine Temperature: -35 to -5 °C

Refrigerant: R404, R134a, Ammonia

Heat Source: Steam / Hot Water / Exhaust Gas / Fuel

Zero Degree Vapour Absorption Chillers

Capacity: 50 – 1000 TR

Heat Source: Steam / Hot Water / Exhaust Gas / Fuel

Chiller + Hot Water Generator

Cooling Capacity: 50 – 2000 TR

Heating Capacity: 130 – 5275 kW

Heat Source: Steam / Hot Water / Exhaust / Fuel

Ultra Low Pressure Vapour Absorption Chiller

Capacity: 50 – 1000 TR

Heat Source: CP Vapour / Ultra Low Pressure Steam

Steam Pressure:

Product Description

Kirloskar’s Ultra Efficient Vapour Absorption Chillers are engineered to deliver cooling and heating solutions by utilizing untapped recoverable energy or live energy such as steam, hot water, and exhaust gas. This allows customers to dramatically reduce power consumption for cooling and heating, while also significantly reducing carbon footprints, Kirloskar’s Vapour Absorption Chillers operate on an advanced Para- flow design. This design ensures that there is no condition of low temperature and high concentration which makes the chiller crystallization free, ensuring the consistent, uninterrupted performance of the vapour absorption chiller. Kirloskar Vapour Absorption Chillers are widely used in all types of industrial facilities that generate waste heat, such as petrochemical, paper, food processing, and steel manufacturing, and in large commercial facilities. These advanced chillers are designed to optimize energy use and significantly reduce operational costs, setting new industry standards for efficiency and reliability and meeting customers’ requirements around the world.

Steam Driven Vapour Absorption Chillers

Single Effect Steam Driven Vapour Absorption Chiller

Capacity: 50 – 2000 TR

Heat Source: Steam

Steam Pressure: 0.5 – 3.0 kg/cm2(g)

COP: 0.75

Double Effect Steam Driven Vapour Absorption Chiller

Capacity: 50 – 2000 TR

Heat Source: Steam

Steam Pressure: 3.5 – 8.0 kg/cm2(g)

COP: 1.5

Hot Water Driven Vapour Absorption Chillers

Double Lift Hot Water Driven Vapour Absorption Chiller

Capacity: 50 – 1000 TR

Heat Source: Hot Water

Hot Water Temperature: 700c

COP: 0.41 to 0.71

Single Effect Hot Water Driven Vapour Absorption Chiller

Capacity: 50 – 1500 TR

Heat Source: Hot Water

Hot Water Temperature: 80 – 1200c

COP: 0.75

Double Effect Hot Water Driven Vapour Absorption Chiller

Capacity: 50 – 1500 TR

Heat Source: Hot Water

Hot Water Temperature: 160 – 1800c

COP: 1.5

Customized Offerings

Composite Chiller

Capacity: 25 – 200 TR

Brine Temperature: -35 to -5 °C

Refrigerant: R404, R134a, Ammonia

Heat Source: Steam / Hot Water / Exhaust Gas / Fuel

Zero Degree Vapour Absorption Chillers

Capacity: 50 – 1000 TR

Heat Source: Steam / Hot Water / Exhaust Gas / Fuel

Chiller + Hot Water Generator

Cooling Capacity: 50 – 2000 TR

Heating Capacity: 130 – 5275 kW

Heat Source: Steam / Hot Water / Exhaust / Fuel

Ultra Low Pressure Vapour Absorption Chiller

Capacity: 50 – 1000 TR

Heat Source: CP Vapour / Ultra Low Pressure Steam

Steam Pressure:

Steam Driven Vapour Absorption Chillers

Single Effect Steam Driven Vapour Absorption Chiller

Capacity: 50 – 2000 TR

Heat Source: Steam

Steam Pressure: 0.5 – 3.0 kg/cm2(g)

COP: 0.75

Double Effect Steam Driven Vapour Absorption Chiller

Capacity: 50 – 2000 TR

Heat Source: Steam

Steam Pressure: 3.5 – 8.0 kg/cm2(g)

COP: 1.5

Hot Water Driven Vapour Absorption Chillers

Double Lift Hot Water Driven Vapour Absorption Chiller

Capacity: 50 – 1000 TR

Heat Source: Hot Water

Hot Water Temperature: 700c

COP: 0.41 to 0.71

Single Effect Hot Water Driven Vapour Absorption Chiller

Capacity: 50 – 1500 TR

Heat Source: Hot Water

Hot Water Temperature: 80 – 1200c

COP: 0.75

Double Effect Hot Water Driven Vapour Absorption Chiller

Capacity: 50 – 1500 TR

Heat Source: Hot Water

Hot Water Temperature: 160 – 1800c

COP: 1.5

Customized Offerings

Composite Chiller

Capacity: 25 – 200 TR

Brine Temperature: -35 to -5 °C

Refrigerant: R404, R134a, Ammonia

Heat Source: Steam / Hot Water / Exhaust Gas / Fuel

Zero Degree Vapour Absorption Chillers

Capacity: 50 – 1000 TR

Heat Source: Steam / Hot Water / Exhaust Gas / Fuel

Chiller + Hot Water Generator

Cooling Capacity: 50 – 2000 TR

Heating Capacity: 130 – 5275 kW

Heat Source: Steam / Hot Water / Exhaust / Fuel

Ultra Low Pressure Vapour Absorption Chiller

Capacity: 50 – 1000 TR

Heat Source: CP Vapour / Ultra Low Pressure Steam

Steam Pressure:

Related Sectors

Automobiles

Biotechnology

Chemicals

Climate Change

Drugs & Pharmaceuticals

Energy

Fast Moving Consumer Goods (FMCG)

Food Processing

Healthcare

Hydrocarbons

Leather and Leather Products

Manufacturing

Oil and Gas

Petroleum

Plastics

Power

Renewable Energy

Steel & Non-Ferrous Metals

Textiles & Apparel

Brand

Kirloskar Pneumatic Company Limited

Modal Number

VAC - Vapour Absorption Chillers

Usage Application

For Industrial Process Cooling Applications Using Waste / Live or Recovery Based Heat Sources

About the Company

Login to see seller contact details.