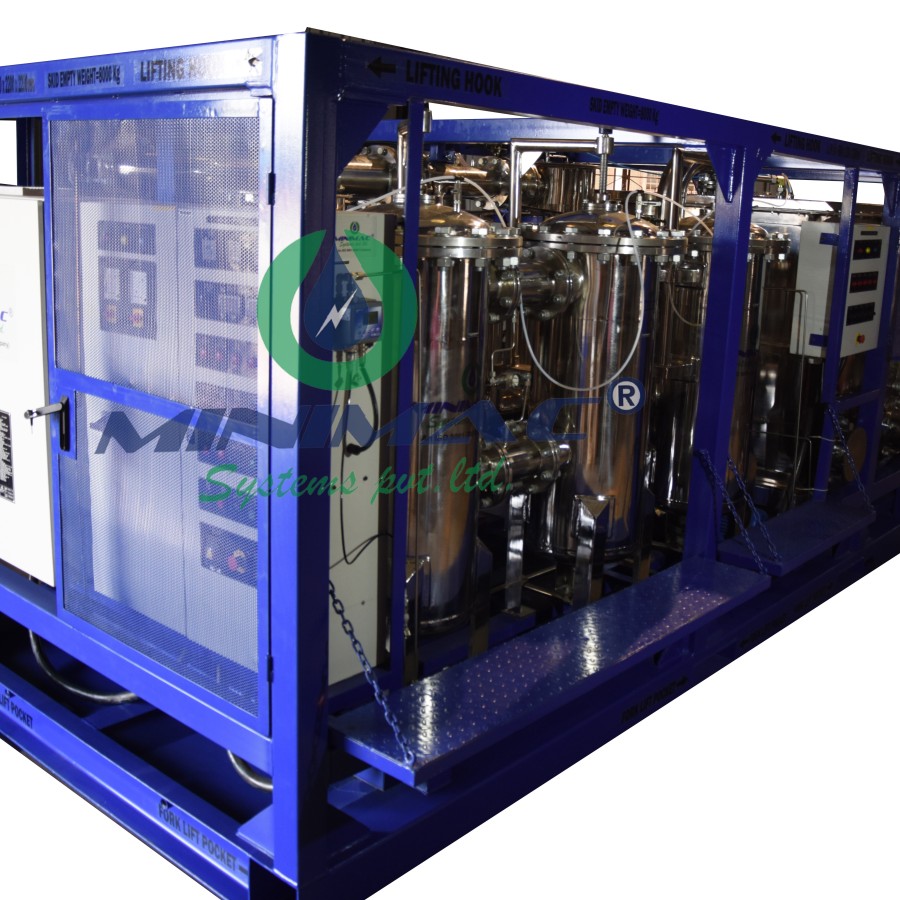

Chemical Flushing System

By MINIMAC SYSTEMS PVT LTD

CCS Series:

The Chemical Cleaning System works on high velocity flushing technology to clean chamber/interior, pipe system, cavity of a component. Minimac’s Chemical Cleaning Systems are designed and developed equipment which have the pumping, filtration and heating capability thereby to create turbulence inside the pipelines to be flushed.

This technology has its application on chemical cleaning too along with lube oil flushing, hydraulic oil flushing, water glycol flushing and water flushing. The key element for right product offering depends on the requirement of the client and the diameters of the pipeline as well as the fluid which has to be used for flushing. One can be assured of a trouble free start-up and prolonged equipment life, with extended time periods before maintenance.

Applications:

Under PPS operations

Upstream, midstream, downstream & petrochemicals (oil & gas)

Power generation

Pipelines and pumps of turbine lube oil system

The Chemical Cleaning System works on high velocity flushing technology to clean chamber/interior, pipe system, cavity of a component. Minimac’s Chemical Cleaning Systems are designed and developed equipment which have the pumping, filtration and heating capability thereby to create turbulence inside the pipelines to be flushed.

This technology has its application on chemical cleaning too along with lube oil flushing, hydraulic oil flushing, water glycol flushing and water flushing. The key element for right product offering depends on the requirement of the client and the diameters of the pipeline as well as the fluid which has to be used for flushing. One can be assured of a trouble free start-up and prolonged equipment life, with extended time periods before maintenance.

Applications:

Under PPS operations

Upstream, midstream, downstream & petrochemicals (oil & gas)

Power generation

Pipelines and pumps of turbine lube oil system

Product Description

CCS Series:

The Chemical Cleaning System works on high velocity flushing technology to clean chamber/interior, pipe system, cavity of a component. Minimac’s Chemical Cleaning Systems are designed and developed equipment which have the pumping, filtration and heating capability thereby to create turbulence inside the pipelines to be flushed.

This technology has its application on chemical cleaning too along with lube oil flushing, hydraulic oil flushing, water glycol flushing and water flushing. The key element for right product offering depends on the requirement of the client and the diameters of the pipeline as well as the fluid which has to be used for flushing. One can be assured of a trouble free start-up and prolonged equipment life, with extended time periods before maintenance.

Applications:

Under PPS operations

Upstream, midstream, downstream & petrochemicals (oil & gas)

Power generation

Pipelines and pumps of turbine lube oil system

The Chemical Cleaning System works on high velocity flushing technology to clean chamber/interior, pipe system, cavity of a component. Minimac’s Chemical Cleaning Systems are designed and developed equipment which have the pumping, filtration and heating capability thereby to create turbulence inside the pipelines to be flushed.

This technology has its application on chemical cleaning too along with lube oil flushing, hydraulic oil flushing, water glycol flushing and water flushing. The key element for right product offering depends on the requirement of the client and the diameters of the pipeline as well as the fluid which has to be used for flushing. One can be assured of a trouble free start-up and prolonged equipment life, with extended time periods before maintenance.

Applications:

Under PPS operations

Upstream, midstream, downstream & petrochemicals (oil & gas)

Power generation

Pipelines and pumps of turbine lube oil system

Related Sectors

Aerospace

Automobiles

Bio Fuels

Biotechnology

Chemicals

Defence

Energy

Engineering

Environment

Manufacturing

Mining

MNC

Plastics

Power

Renewable Energy

Research & Development

Steel & Non-Ferrous Metals

Technology

Textiles & Apparel

Water

Brand

Minimac Systems Pvt Ltd

Material

SS/MS

Usage Application

Chemical Flushing

Warranty

12 Months

Flow rate

Customisable

About the Company

We are an ISO 9001:14001:45001 certified supplier, distributor, manufacturer, exporter and trader of Oil Purification & Reconditioning Plants, Laser Particle Counters and Allied Machines.

Minimac Systems Pvt. Ltd., a leading provider of oil purification and reconditioning solutions, delivers precision-engineered equipment and services to industries worldwide. Founded in 2012 and headquartered in Pune, India, we are ISO 9001:14001:45001 certified, underscoring our commitment to quality, environment, and safety.

Our comprehensive range includes:

We offer the Best-In-Class, Versatile, Application Compatible, Cost-Efficient Equipment for Contamination Control in Lube Oils, Hydraulic Oils, Control Fluids (FRF), and Gear Oils. Our offerings include:

1. Oil Purification Systems2. Flushing Systems 3. Oil Filters4. Oil Testing & Monitoring Instruments5. O&M Services

Leveraging advanced technology and a skilled workforce, we provide tailored solutions to optimize equipment performance, extend oil life, and reduce downtime.

Our global footprint, spanning from Australia/NZ to the Indian Subcontinent and East/Middle Africa, reflects our dedication to serving clients worldwide.

Minimac Systems Pvt. Ltd., a leading provider of oil purification and reconditioning solutions, delivers precision-engineered equipment and services to industries worldwide. Founded in 2012 and headquartered in Pune, India, we are ISO 9001:14001:45001 certified, underscoring our commitment to quality, environment, and safety.

Our comprehensive range includes:

We offer the Best-In-Class, Versatile, Application Compatible, Cost-Efficient Equipment for Contamination Control in Lube Oils, Hydraulic Oils, Control Fluids (FRF), and Gear Oils. Our offerings include:

1. Oil Purification Systems2. Flushing Systems 3. Oil Filters4. Oil Testing & Monitoring Instruments5. O&M Services

Leveraging advanced technology and a skilled workforce, we provide tailored solutions to optimize equipment performance, extend oil life, and reduce downtime.

Our global footprint, spanning from Australia/NZ to the Indian Subcontinent and East/Middle Africa, reflects our dedication to serving clients worldwide.

Login to see seller contact details.