QFORM EXTRUSION SOFTWARE

By DDSPLM PVT LTD

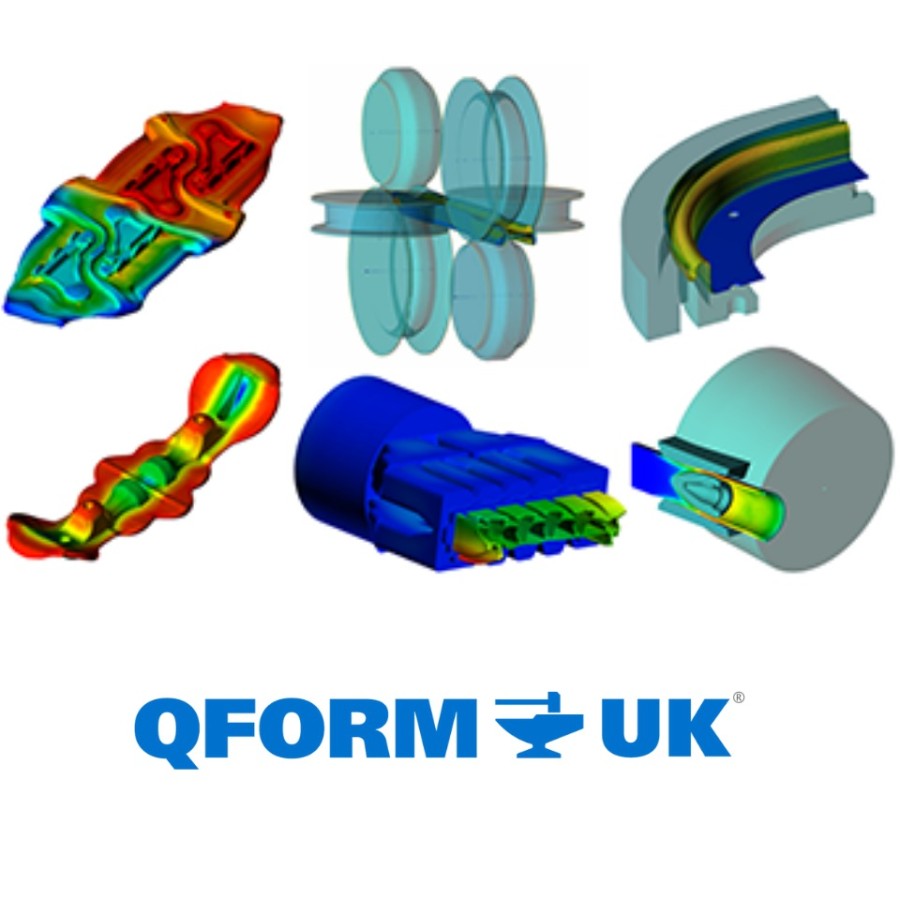

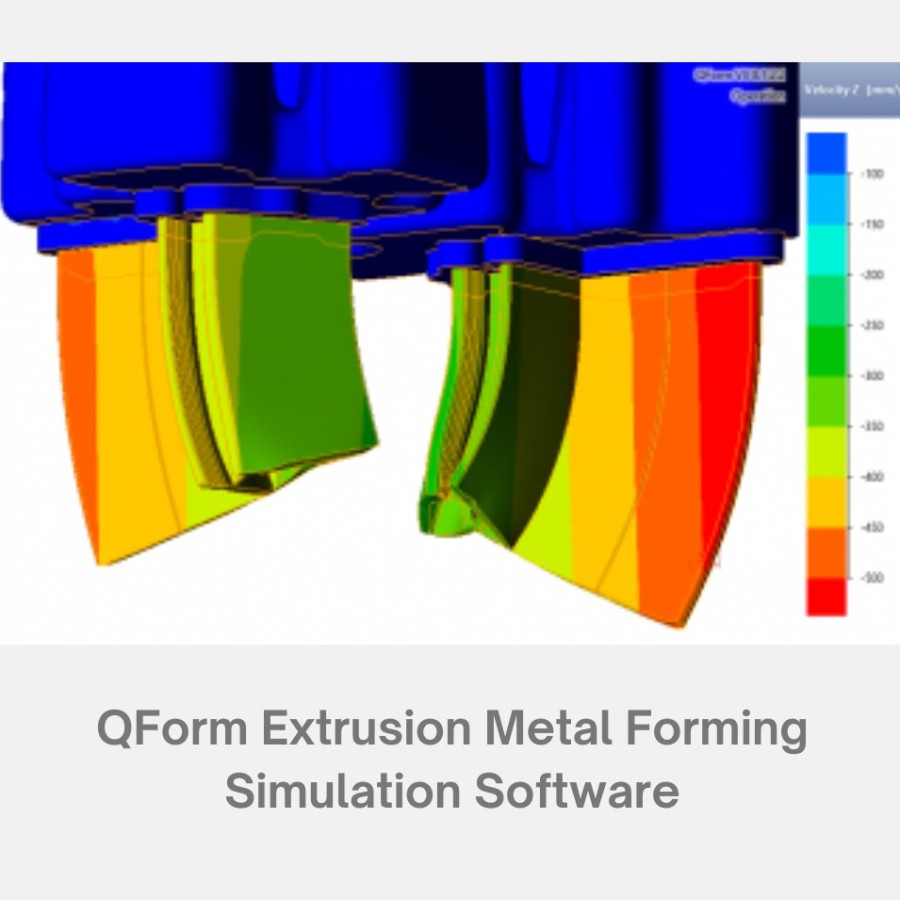

The tools for complex extrusion profiles can take a long time to design properly. The use of simulation software significantly speeds up the development time of extrusion tooling and also predicts the quality of the extruded product.

QForm Extrusion is the only program in the market that can perform simulations of material flow that are thermally and mechanically coupled to the die deformation even for very complicated thin walled profiles. QForm Extrusion was developed for simulation analysis of material flow during the extrusion process and for analysis of the stress-strain-state of die set. The program features parametric representation of the bearing geometry and state-of-the-art automatic meshing algorithms. By keeping the bearing geometry as a parametric surface, QForm Extrusion is able to consider cases when die deformation causes local zones of very fine inclination of choke or relief that may vary by just a few angular minutes.

QForm Extrusion is the only program in the market that can perform simulations of material flow that are thermally and mechanically coupled to the die deformation even for very complicated thin walled profiles. QForm Extrusion was developed for simulation analysis of material flow during the extrusion process and for analysis of the stress-strain-state of die set. The program features parametric representation of the bearing geometry and state-of-the-art automatic meshing algorithms. By keeping the bearing geometry as a parametric surface, QForm Extrusion is able to consider cases when die deformation causes local zones of very fine inclination of choke or relief that may vary by just a few angular minutes.

Product Description

The tools for complex extrusion profiles can take a long time to design properly. The use of simulation software significantly speeds up the development time of extrusion tooling and also predicts the quality of the extruded product.

QForm Extrusion is the only program in the market that can perform simulations of material flow that are thermally and mechanically coupled to the die deformation even for very complicated thin walled profiles. QForm Extrusion was developed for simulation analysis of material flow during the extrusion process and for analysis of the stress-strain-state of die set. The program features parametric representation of the bearing geometry and state-of-the-art automatic meshing algorithms. By keeping the bearing geometry as a parametric surface, QForm Extrusion is able to consider cases when die deformation causes local zones of very fine inclination of choke or relief that may vary by just a few angular minutes.

QForm Extrusion is the only program in the market that can perform simulations of material flow that are thermally and mechanically coupled to the die deformation even for very complicated thin walled profiles. QForm Extrusion was developed for simulation analysis of material flow during the extrusion process and for analysis of the stress-strain-state of die set. The program features parametric representation of the bearing geometry and state-of-the-art automatic meshing algorithms. By keeping the bearing geometry as a parametric surface, QForm Extrusion is able to consider cases when die deformation causes local zones of very fine inclination of choke or relief that may vary by just a few angular minutes.

Export Countries

India

Related Sectors

Auto Components

Information & Communication Technology

Manufacturing

Research & Development

Technology

Availability

Yes

Brand

QForm

About the Company

Login to see seller contact details.